Introduction

Warehouse efficiency directly impacts delivery speed, cost control, and customer satisfaction. Whether you’re running a small stockroom or a large fulfillment center, these 10 tips will help improve productivity and reduce operational headaches.

1. Use a Warehouse Management System (WMS)

A WMS centralizes inventory control, helps track movements, and improves order accuracy.

2. Optimize Your Layout

Design your warehouse for flow — receiving, storage, picking, and shipping areas should be clearly defined and logically connected.

3. Invest in Barcode & RFID Technology

Automated scanning reduces picking errors, speeds up receiving, and ensures real-time updates.

4. Train Your Staff Continuously

Regular training improves safety, reduces mistakes, and boosts morale.

5. Implement Slotting Optimization

Place fast-moving items closer to the packing station to reduce travel time.

6. Maintain Cleanliness and Safety

A clean warehouse is not just professional — it’s safer and more efficient.

7. Set Performance Metrics

Track KPIs such as:

Pick accuracy

Orders per hour

Inventory turnover rate

8. Reduce Manual Handling

Use forklifts, conveyors, and carts wherever possible to minimize injuries and improve speed.

9. Plan for Seasonal Peaks

Forecast demand and scale up resources during high-sales periods.

10. Automate Where Possible

Start small — label printing, reordering alerts, or stock level notifications — and scale up.

Conclusion

Efficiency doesn’t happen by accident. It comes from planning, training, and adopting best practices. These steps will help you run a streamlined, safe, and scalable warehouse operation.

Powered by Froala Editor

Related Insights & Articles

July 14, 2025

At vero eos et accusamus et iusto odio dignissimos ducimus qui blanditiis praesentium

At vero eos et accusamus et iusto odio dignissimos ducimus qui blanditiis praesentium voluptatum deleniti atque corrupti quos dolores et quas molestias excepturi sint occaecati cupiditate non provident, similique sunt in culpa qui officia deserunt mollitia animi, id est laborum et dolorum fuga. Et harum quidem rerum facilis est et expedita distinctio. Nam libero tempore, cum soluta nobis est eligendi optio cumque nihil impedit quo minus id quod maxime placeat facere possimus, omnis voluptas assumenda est, omnis dolor repellendus. Temporibus autem quibusdam et aut officiis debitis aut rerum necessitatibus saepe eveniet ut et voluptates repudiandae sint et molestiae non recusandae. Itaque earum rerum hic tenetur a sapiente delectus, ut aut reiciendis voluptatibus maiores alias consequatur aut perferendis doloribus asperiores repellat.

July 18, 2025

The Future of Warehousing — Embracing Automation and AI

Introduction

Warehousing is no longer just about storage — it's about speed, accuracy, and adaptability. As e-commerce grows and supply chains globalize, the demand for faster and smarter warehouse operations is transforming the entire industry. Automation and AI are no longer luxuries — they are becoming essential tools for modern warehouses.

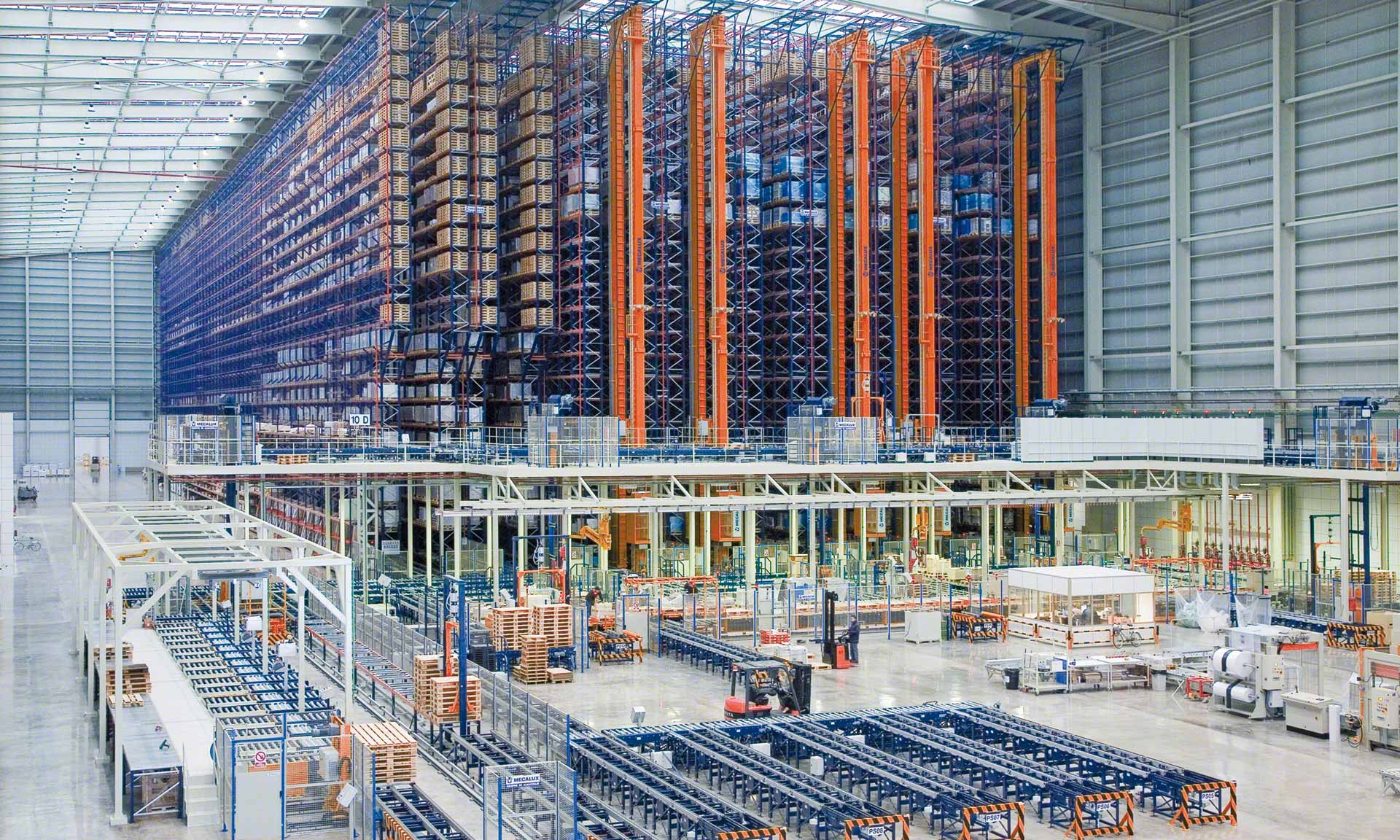

The Rise of Smart Warehouses

Smart warehouses use a combination of sensors, AI software, robotics, and data analytics to automate repetitive tasks like picking, packing, inventory tracking, and shipment scheduling.

For instance, companies like Amazon use robotic arms and shelf-carrying robots to optimize picking paths and reduce manual effort. With advanced machine learning, these systems can learn and adapt over time, further improving their performance.

Benefits of Automation

Increased Speed: Robots and automated conveyors work 24/7 without breaks.

Improved Accuracy: AI-based systems reduce human error in order picking.

Better Space Utilization: Automated vertical storage solutions can save valuable floor space.

Cost Savings: While upfront investments are high, long-term savings on labor and time are substantial.

Challenges in Adopting AI

Despite its advantages, automation isn’t without its challenges:

High Initial Investment

Integration with Legacy Systems

Skilled Labor Shortage

Ongoing Maintenance Costs

AI in Action: Real-World Examples

Alibaba's Smart Warehouse: Staffed by 700 robots, reducing labor costs by 70%.

Ocado's Grid System: Fully automated grocery fulfillment with 24/7 operations.

What’s Next for Warehousing?

Drones for Inventory Checks

Blockchain for Transparent Supply Chains

Autonomous Forklifts and Delivery Robots

Predictive AI for Stock Replenishment

Conclusion

Automation and AI are transforming warehousing from a labor-intensive function to a data-driven operation. Businesses that adopt these technologies today will lead tomorrow’s supply chain innovations.

Powered by Froala Editor

July 18, 2025

Why Inventory Management Can Make or Break Your Business

Introduction

Inventory management might sound like a backend process, but its impact is visible at the front lines — especially when customers experience out-of-stock items or delayed deliveries. Efficient inventory handling is not just a part of logistics, it’s a key driver of profitability, customer satisfaction, and operational stability.

The Real Cost of Poor Inventory Control

Overstocking: Ties up capital, increases storage costs, and leads to product waste (especially for perishable goods).

Understocking: Causes stockouts, lost sales, and damages brand credibility.

Hidden Costs: Time spent searching for misplaced items, employee inefficiencies, and warehouse errors.

Modern Solutions for Smarter Inventory

Cloud-Based Inventory Systems: Access real-time data from any device, anywhere.

Barcode/RFID Scanning: Speeds up tracking and minimizes manual entry errors.

AI & Predictive Analytics: Forecast demand more accurately using historical data and trends.

Inventory Management Strategies

ABC Analysis: Categorize inventory into 3 groups (A - high value, B - moderate, C - low value).

FIFO vs. LIFO: Choose a method based on your industry to manage stock rotation.

Safety Stock: Always keep a buffer stock to handle supply chain disruptions.

Common Mistakes to Avoid

Relying on spreadsheets

Ignoring seasonal demand shifts

Lack of proper audits

No clear reorder points

Tools & Technologies to Consider

ERP systems like SAP, Oracle, or Zoho

Mobile inventory apps for scanning and stocktaking

IoT sensors for real-time monitoring

Conclusion

Inventory is not just about what’s in your warehouse — it's about business control. Smarter inventory practices save money, improve service, and allow your business to scale efficiently.

Powered by Froala Editor